John Deere 47-in. Snow Blower For X580, X584, X590 Select Series Lawn Tractors

47-in. Snow Blower

For X580, X584, X590 Select Series Lawn Tractors

- Hydraulic power lift lets you effortlessly lift and lower blower for easier repositioning on larger jobs

- Large 47-inch clearing width and 16-inch tall auger housing provides superior capacity for larger cleanups

- Easily rotate chute and snow deflector for precise snow placement on-the-go

- Cast-iron gear box and shear-bolt protection

-

Get a Quote

Build Your Own

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

-

Payment Calculator

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

-

Share

Print

Features

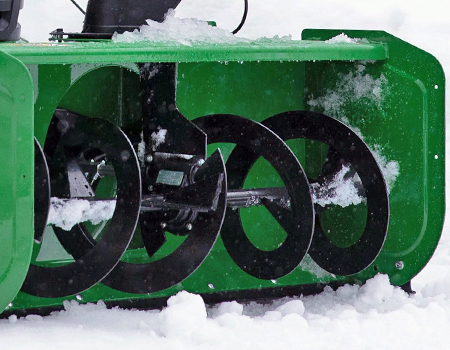

47-in. (119-cm) Snow Blower for 2016 and later X500 Tractors

47-in. (119-cm) Snow Blower (shown with optional drift blade)

47-in. (119-cm) Snow Blower (shown with optional drift blade)

The 47-in. (119-cm) Snow Blower has the capacity to handle big snow removal jobs:

- Works well in all snow conditions and is suited for snow removal around recreational parks, industrial parks, and other applications where snow must be moved greater distances

- Ideal for home and estate owners in heavy snow regions

- More effective than single-stage snow throwers when operating in wet, heavy snow and deep snow conditions; the low speed auger sizes crusted material as it moves snow toward the second-stage blower

- Provides consistent snow placement in variable snow conditions because the high-speed blower gives the discharged snow consistent velocity—even in very light clean-up volumes

For model year 2016 and later X500 Select Series Tractors with hydraulic lift.

Two-stage design

Two-stage auger and cast iron gearbox

Two-stage auger and cast iron gearbox

The low-speed auger picks up snow and moves it toward the center of the machine into the high-speed rotor where it is blown out of the discharge chute.

A cast-iron gearbox provides speed reduction for the auger and is protected by shear bolts for each auger half.

Two-stage snow blowers are more effective than single-stage snow throwers when operating in deep snow as the low-speed auger is used to size crusted material. They also provide consistent snow placement in variable snow conditions because the high-speed rotor gives the discharged snow consistent velocity-even in very light clean-up volumes.

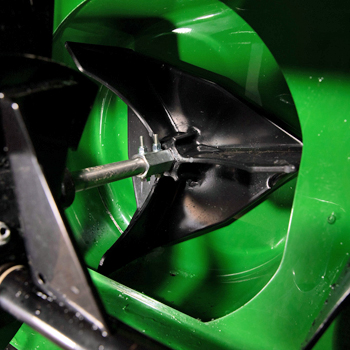

Durable, second-stage blower fan

Durable, second-stage blower fan

Cast-iron gearbox

Cast-iron gearbox

The second-stage blower fan is formed from the same durable and rust-resistant, ultra-high molecular weight (UHMW) polyethylene material proven in the Power Flow™ blower fan for durability and long life.

The durable fan material has the same cold-weather characteristics as snowmobile track rollers and will not bend and cause the fan to get out of balance.

A single-belt drive system coupled to a cast-iron gearbox with a horizontal sheave minimizes belt angles and twists for superior reliability and durability.

Spout and deflector

Spout and deflector

Spout and deflector

Spout rotation and deflector controls

Spout rotation and deflector controls

The discharge spout and deflector are made from high-density polyethylene material that will not dent or rust and resists snow buildup to ensure trouble-free operation. It is more durable, especially in cold-weather use, than the polypropylene material used by some other manufacturers.

Spout direction and deflector angle can both be conveniently controlled form the operator station:

- The chute material remains smooth and is less likely to clog than a steel chute.

- Controls to operate the chute are conveniently located for easy operation.

- The discharge spout can be rotated 200 degrees from the operator station.

- The deflector can be easily adjusted form the operator's station to determine distance of throw.

Adjustable skid shoes

Adjustable skid shoe and cutting edge

Adjustable skid shoe and cutting edge

Skid shoes help control the height of the snow blower cutting edge and are especially helpful for use on gravel drives and irregular surfaces.

Skid shoes can be adjusted by loosening the mounting bolts and positioning them to suit the operating conditions:

- Stamped from heavy-gauge steel for long life

- Securely held in place by two bolts

- Can be adjusted for rough or smooth surface conditions

A heavy-duty steel cutting edge provides a durable wear surface and helps protect the snow blower housing from damage:

- Securely held in place by seven bolts

- Can be easily replaced if necessary

Key specs

| Width | |

|---|---|

| Height of opening | |

| Auger | Diameter 16 in. 40.6 cm Drive Cast-iron bevel gear box Protection Shear bolt for each auger half |

Dimensions

| Width | Overall: 47 in. 119 cm Clearing: 47 in. |

|---|---|

| Height of opening | |

| Height to top of chute deflector | |

| Housing depth | |

| Overall length | |

| Housing thickness | |

| Side panel thickness |

Auger

| Diameter | 16 in. 40.6 cm |

|---|---|

| Speed | |

| Drive | In-line V-belt |

| Auger drive gearbox | Cast-iron bevel gear box |

| Protection | Shear bolt for each auger half |

| Drift knife | Optional for both sides of housing |

| Bearing | Sealed bearings on each end: 0.75 in. 19 mm |

Impeller

| Speed | |

|---|---|

| Diameter |

Blower

| Blower fan drive | Cast-iron right-angle gearbox |

|---|---|

| Speed | |

| Blower fan material | Ultra-high molecular weight (UHMW) polyethylene |

| Blower fan size | 4.75x15 in. 12.1x38.1 cm |

| Bearing | Sealed bearings on each end: 0.75 in. 19 mm |

Scraper blade

| Type | Scraper edge: reversible and replaceable |

|---|

Lift system

| Type | Hydraulic |

|---|---|

| Lift height | 4 in. 102 mm |

Spout

| Diameter | 6 in. 15.2 cm |

|---|---|

| Rotation | To each side: 100 degree (angle) |

| Rotation control | Manual remote handle |

Chute

| Chute control | |

|---|---|

| Chute rotation |

Weight

| Approximate weight | 210 lb 95.26 kg |

|---|

Setup time

| Attaching time | No tools required: 5 minutes |

|---|---|

| Removal time |

Additional information

| Date collected |

|---|

Would you like more information?

Free Parts Delivery to

Drop Boxes!

OUR DEPARTMENTS

DEALER TRANSFER

OUR INVENTORY

OUR PRODUCTS

© Copyright 2017 - 2025 Ballweg Implement All Rights Reserved. Site by EquipmentLocator.com