John Deere DM50 Series Disc Mowers

DM50 Series

Disc Mowers

- Rope System transport latch

- Quick-remove shear hub assembly

- DM5050 & 5060 iMatch and Quick Coupler compatible

- DM5070 Cat. 2 Quick Coupler compatible

-

Get a Quote

Build Your Own

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

-

Payment Calculator

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

- View Product Brochure

-

Share

Print

Features

Simple float spring tension adjustment

DM50 Series float spring tension adjustment

DM50 Series float spring tension adjustment

Set the float spring to get maximum performance during operation. Adjust properly so the down pressure does not damage crop stubble as the skid shoes pass through the field.

Park stand and arm system

Park stand in park position

Park stand in park position

Park stand in operating position

Park stand in operating position

The DM50 Series Disc Mower park stand and parking arm work together to transfer the mower’s weight to the cutterbar while in the parked position. This makes the attachment process easier, saving time and frustration.

Park arm in park position

Park arm in park position

Park arm in operating position

Park arm in operating position

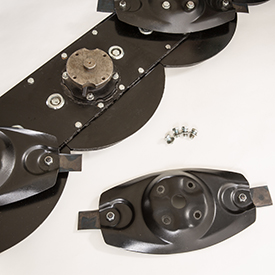

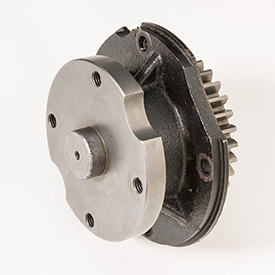

Shear hub assembly serviceability

Oval-shaped disc removed

Oval-shaped disc removed

Cutterbar serviceability is easier on the DM50 Series Disc Mowers. Remove the oval-shaped disc(s) with only four bolts per disc. The shear hub assembly can be serviced by removing the remaining four bolts. This will save time and oil replacement costs by not splitting the entire cutterbar to replace the sheared hubs as required in previous models.

Shear hub assembly on DM50 Series

Shear hub assembly on DM50 Series

Shear hub assembly on DM50 Series

Shear hub assembly on DM50 Series

Take the shear hub assembly off the cutterbar by removing only eight bolts.

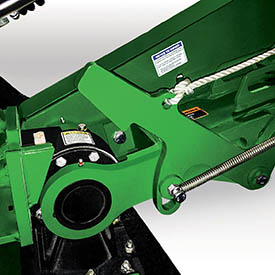

Transport lock system

DM50 in transport position

DM50 in transport position

DM50 in operating position

DM50 in operating position

The transport lock system is a simple mechanical system that saves time and ensures safety. Use the rope system to raise the transport lock, engage selective control valve (SCV) 1 to bring the cutterbar into the transport position, and release the rope system to lock for transport.

Outer swath wheel

Outer swath wheel

Outer swath wheel

Add the outer swath wheel to the DM50 Series Disc Mower to achieve separation between cut and uncut crop. By keeping the cut crop out of the uncut crop, cutting is not happening twice, which would reduce overall productivity. The swath wheel is fully adjustable up and down the length of the cutterbar, and it bolts directly to the top frame with U-bolts.

Dimensions

| Cutting width | 2.36 m 7.7 ft |

|---|---|

| Swath width | 1.75 m 5.7 ft |

| Operation of cutting angle | +/- 25 degree (angle) |

Weight

| Per machine | 442 kg 975 lb |

|---|---|

| Shipping (1 unit and crate) | 998 kg 2,200 lb |

Tractor compatibility

| Minimum PTO | PTO drive rpm 540 rpm 33.6 kW 45 PTO hp |

|---|

Hitch

| Category | Category 1, Category 2 - iMatch and Quick-Coupler compatible |

|---|---|

| Type | 3-point |

Cutterbar

| Lift mechanism | Hydraulic |

|---|

Cutting discs

| Quantity | Six |

|---|---|

| rpm | 3,000 rpm |

Knives

| Quantity | 12 |

|---|

V-belts with tensioner

| Quantity | Four |

|---|

Set-up time (per unit)

| Labor hours | 1 |

|---|

Warranty

| Time period | 1 year |

|---|

Additional information

| Date collected |

|---|

Would you like more information?

Free Parts Delivery to

Drop Boxes!

OUR DEPARTMENTS

DEALER TRANSFER

OUR INVENTORY

OUR PRODUCTS

© Copyright 2017 - 2025 Ballweg Implement All Rights Reserved. Site by EquipmentLocator.com