John Deere L331 Large Square Baler

L331

Large Square Baler

- Bale Documentation with John Deere Operations Center™

- MegaWide™ pickup with MegaTough™ pickup teeth

- John Deere moisture sensor and weighing system

- BalerAssist™ drivetrain system

-

Get a Quote

Build Your Own

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

-

Payment Calculator

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

- View Product Brochure

-

Share

Print

Features

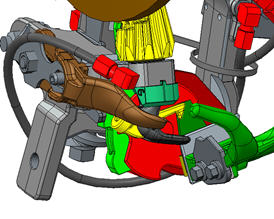

MegaWide™ pickup with MegaTough™ pickup teeth provide added durability

MegaWide pickup

MegaWide pickup

MegaWide pickup

MegaWide pickup

The pickup is designed and built by John Deere in Ottumwa, Iowa. The John Deere MegaWide large square balers (LSBs) pickups use a low-profile pickup drum with a large-diameter roller baffle to efficiently pick crop up from the field. The performance of the roller baffle compressing the crop against the pickup tines means more crop in the bale and fewer leaves and crop left in the field.

- 2.2-m (7.2-ft) wide pickup is available on the L331R and L341R Baler

- Available with standard or premium components

- Tooth-to-tooth width is 1.92 m (76 in.)

- Eight staggered tooth bars help prevent overload

- Standard semi-pneumatic fixed gauge wheels provide smooth ground gauging over uneven terrain and protection to the pickup

- 2.5-m (8.1-ft) wide pickup is available on the L341R Baler

- Available only with premium components

- Tooth-to-tooth width is 2.18 m (86 in.)

- Eight staggered tooth bars help prevent overload

- Standard semi-pneumatic pivoting gauge wheels reduce sliding and scuffing of the tires in the field when the baler turns

- MegaWide pickup makes it easier to produce better-shaped bales and improves crop pickup in wide, windblown, or scattered windrows

- MegaTough pickup teeth provide greater strength and durability

- Chain driven for positive feeding

- Mechanical cutout clutch protection for added durability

MegaTough pickup teeth

MegaTough pickup teeth

Mega and MegaTough pickup teeth are base equipment:

- Mega pickup teeth, at the ends of the pickup, are heavy-duty for long life and improved crop retrieval

- MegaTough pickup teeth are designed to withstand the harshest baling conditions and provide long service life

Both pickup widths use a heavy, C-channel construction for the toothbar assembly. The pickup toothbars are divided into two half sections that mount to a center spider for increased strength and even crop feeding.

Semi-pneumatic gauge wheels

Semi-pneumatic gauge wheels

Semi-pneumatic gauge wheels provide smooth ground gauging over uneven terrain and protection to the pickup.

- Stiffer rubber sidewalls

- No air pressure to maintain, which means no flat tires

- Adjustable to meet pickup tooth-to-stubble height requirements

Converging wheels are available on the 2.2-m (7.2-ft) pickup to increase the overall feeding width to 2.8 m (9.2 ft):

- Rubber-mounted steel tines offer better durability

- Tines are sized to prevent dirt buildup

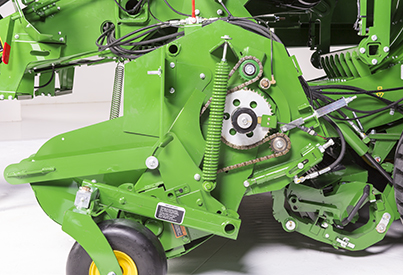

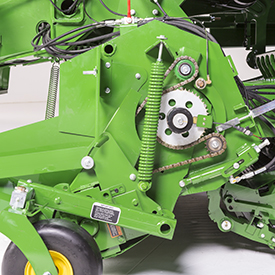

Pickup float springs

Pickup float springs

Pickup float springs

Pickup float springs

The pickup float springs are positioned for excellent flotation.

- Adjustable to meet varying field conditions

- Float springs only support the pickup reel

- Rotor assembly is fixed to the baler frame, eliminating additional weight on the pickup system

Premium MegaWide™ pickup

The premium MegaWide pickup is available for the L331 and L341 Large Square Balers. The premium pickup offers larger components to increase the durability and reliability of the pickup.

Changes to the premium MegaWide pickup include:

- Larger cams and cam bearings

- Larger spider gears

Reel cam and cam arms for premium machines

Reel cam and cam arms for premium machines

Left-hand spider gears

Left-hand spider gears

Right-hand spider gears

Right-hand spider gears

The spider gears on the premium pickup have bearings that give the reel increased durability (longer life), as well as offering a more quiet operation of the pickup. The spider gears are also larger in diameter for increased life.

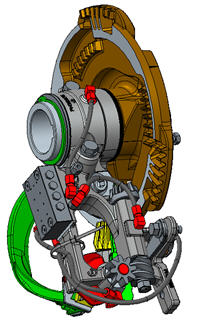

Double-tie knotter system provides reliable knotting in high density and the most difficult baling conditions

Double-tie knotter system

Double-tie knotter system

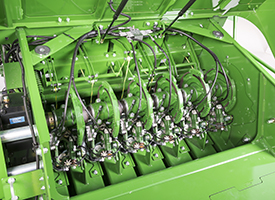

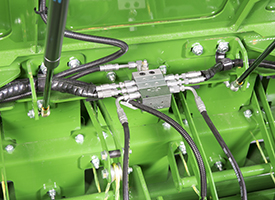

Knotter grease block

Knotter grease block

L331R and L341R Large Square Balers (LSBs) come standard with double-tie knotters.

John Deere-designed knotters are designed for performance, reliability, and reduced maintenance requirements. The auto-lube system is integrated into the knotter frames, and two internal grease ports reduce the time spent on pre-baling maintenance.

Integration of the lube system block into the knotter frame reduces the number of grease lines required for each knotter.

The integrated grease block results in a reduction in the amount of grease lines required to grease the knotter system and the number of grease line connection points. Fewer feet of grease lines and fewer connection points mean less maintenance and more time baling.

Knotting system

Knotting system

If service to the knotter stack is required, the knotters are positioned using an adjustment screw instead of shims. This saves time by having the ability to make adjustments at any point of assembly.

Split knotter frame

Split knotter frame

The split knotter frame is directly mounted to the intermittent gear so the frame can be removed without servicing the knotter stack.

Billhook cam

Billhook cam

Like the John Deere single-tie knotter, the billhook cam and wiper arm plate are removable and individually serviceable. This allows replacement without replacing large castings or assemblies.

Instances where competitors must adjust the wiper arm to the billhook with a hammer, the John Deere solution allows the setting to be made with two bolts. This provides a more precise and repeatable setting, which results in more consistent knot wipe-offs.

| L331 | L341 | |

| Connection point reduction | 8 | 12 |

| Lube line reduction (m, ft) | 16.8 m (55 ft) |

25.3 m (83 ft) |

The one series LSBs store twine in single-row twine boxes. The twine is then routed to the sealed gear tensioners. The sealed tensioner gears have been proven to provide more consistent twine tension during knot formation. This increases knotter performance and consistency. Once the correct bale length is achieved, the tie system clutch is activated.

Knotter trip system

The John Deere-designed double-tie knotting system is gear and driveline driven to ensure the needle-to-plunger timing is maintained throughout the life of the baler.

The needle lift crank and clutch rocker arm are made of hardened cast iron to improve strength and durability of the knotter clutch. The gearbox drives the system around 360 degrees to complete a tie.

Knotter trip system

Knotter trip system

On the L331R and L341R Large Square Balers, the producer can choose between a mechanical trip system or an electrical trip system.

The electrical trip system offers the following advantages:

- Bale length adjustment from the cab

- Tying off the last bale from the cab

- Reduction in maintenance requirements

- Improved length accuracy

- Predictive tie

- Predictive tie takes into account the flake size throughout the bale and desired length of bale. When a bale is approaching the desired length and the next flake will put it at or over the desired length, predictive tie will trip the tie system. Whereas the mechanical system has to pass the desired length then it will tie on the next flake.

Baler monitor system is International Standard Organization Bus (ISOBUS) compatible

John Deere large square balers (LSBs) are ISOBUS compatible which enables them to work with any ISOBUS monitor system.

Baler control can also be incorporated into the CommandCenter™ on R Series Tractors as long as the tractor is ordered ISOBUS ready (GS-ready wiring harness option code 8064 or GS AutoTrac™-ready wiring harness option code 8067on 6R Tractors).

Current GreenStar™ (GS) displays, including the touchscreen 2630, 1800 as well as the GS 2600, are compatible for customers who already own a John Deere ISOBUS display.

The display main screen is user selectable allowing for customization so the customer sees what they want where they want. With more information available from the moisture and weighing systems the operator can select what they care most about.

The new menu is controlled over what softkeys are shown on the main page allowing users to navigate to what they need faster and easier.

Balers that will be utilized on non-ISO tractors will require a GS display as well as a conversion harness to connect the display and the baler.

One series LSBs offer a manual pressure control mode, allowing the operator to continue baling in the event of an electrical failure.

Information and adjustments available on the display:

- Driving direction arrows are shown across the top of the screen, helping the operator create a more uniform bale.

- Electronic knotter flags are standard on all John Deere balers. This feature offers convenience to operators by allowing for true look-ahead baling.

- Feedback on the flywheel brake, precutter functions (if equipped), greasing, lighting, bale chute (if equipped), and bale drop (if equipped) systems.

- Bale weights and bale moisture are displayed when their respective options are purchased.

- Control of the drop floor on the precutter rotor option.

- Electronic tie control from the cab.

- Preservative applicator monitoring and adjustments.

- Machine faults are shown in red on the screen allowing the user to quickly detect any issues.

- Bale count is selectable between the current field, customer, season, or lifetime bale counts.

PhiBer accumulator integration into the baler display.

PhiBer is a trademark of PhiBer Manufacturing Inc.

Moisture sensor

Moisture sensor

Moisture sensor

The John Deere integrated moisture sensor for large square balers provides bale moisture levels throughout the baling process. Mounted forward in the bale chamber, it provides timely information for real-time decisions. This sensor was designed by John Deere specifically for the application, and uses an integrated display for less clutter in the cab. It operates in a complete range of moistures from dry to wet crops.

This sensor can be used in conjunction with the John Deere preservative system to adjust application rates.

Weighing system

The John Deere bale weighing system provides bale weights throughout the baling process. With sensors mounted to the pre-compression chamber floor, it provides bale weights on a flake-by-flake basis. Knowing the flake weight helps the operator make more consistent bales. The current bale weight and previous bale weights can be displayed on the monitor.

Preservative applicator

Preservative tank

Preservative tank

Preservative application allows harvesting hay at slightly higher moisture levels without worrying about spoilage or heat. Using preservative increases the baling window by allowing operators to begin baling earlier in the day and continue baling later into the evening, this greatly decreases the dependency on weather. This application system is capable of preserving hay up to a 27 percent moisture level without compromising hay quality.

NOTE: Care must be exercised not to exceed the moisture levels recommended by preservative manufacturers in order to avoid spoilage.

Crop detection sensors

Crop detection sensors

The one series LSB offers a John Deere designed preservative application system. The John Deere system is integrated with the John Deere moisture sensor. The high-accuracy moisture sensor enables more accurate application of preservative. Crop detection sensors detect crop to ensure that preservative is only being applied when crop is present.

Preservative system installation

Preservative system installation

Factory installation of the preservative system is available and eliminates any baler modifications that were previously required when performing a dealer installation. The factory installation tests all electrical components of the preservative system before it leaves the factory.

The preservative applicator includes the following:

- 567-L (150-U.S. gal.) poly tank 12-V diaphragm-type pump

- Integration into John Deere electronics

- Service parts available through the John Deere Dealer Network

- ExactApply™ nozzles for even distribution

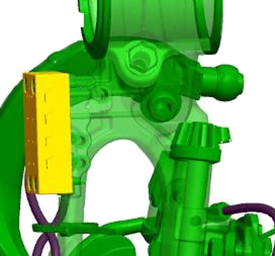

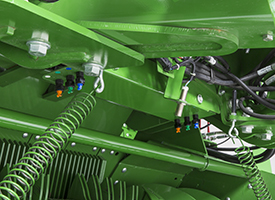

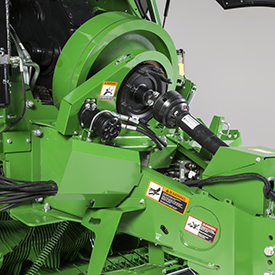

BalerAssist

The BalerAssist drivetrain system is an industry-exclusive offering that gives the operator the ability to hydraulically control the drivetrain. The system is able to operate in both the forward direction as well as the reverse direction and at two speeds each direction with a maximum speed of about 4 plunger strokes per minute.

John Deere value:

- Reduced time to remove plugs that occur in the pickup or rotor by backing the plug out

- Reduced time to perform maintenance and time the baler

- Increased ability to troubleshoot knotters by performing slower tie cycles

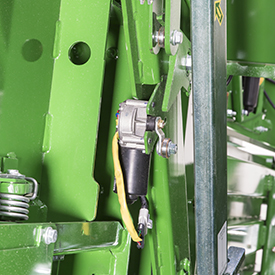

The BalerAssist drivetrain system can be controlled from the display or from a Bluetooth® wireless system remote.

- Once BalerAssist is enabled from the display, it can be controlled by the Bluetooth remote

- Bluetooth remote is included when the option is ordered

From the display, speed adjustments can be made to the following categories:

- Slow forward

- Fast forward

- Slow reverse

- Fast reverse

BalerAssist Bluetooth remote

BalerAssist Bluetooth remote

The Bluetooth remote has the following functions with icons that match the display:

- Enable

- Slow forward

- Fast forward

- Slow reverse

- Fast reverse

- Service lights can be turned on using the remote

Bluetooth is a trademark of Bluetooth SIG Incorporated.

Wear parts box

A wear parts box will be available for the L331R and L341R Large Square Balers (LSBs). The wear parts box includes 18 of the most common wear parts identified by customer support and engineering. Having these parts on hand will help producers keep their balers running during the season. The parts box is an option that can be ordered when configuring the baler.

NOTE: The wear parts box is for the one series baler. A lot of the parts included in the box are not able to be retrofit to the L330 or L340.

Parts come packaged in a durable container that can be used in the truck, shop, or field.

Magnetic parts lists help producers keep track of parts they need.

Parts included:

| Part | Quantity |

| Pickup teeth | 20 |

| Pickup strippers | 4 |

| Pickup stripper bolts | 4 |

| Left-hand cam arm | 1 |

| Right-hand cam arm | 1 |

| Cam arm bearing | 4 |

| Cam arm bolt | 2 |

| Bill hooks | 6 |

| Wiper plates | 6 |

| Twine knives | 6 |

| Twine discs | 3 |

| Twine retainer | 3 |

| Twine cleaner | 3 |

| Needle roller kit | 6 |

| Proximity sensor | 2 |

| Bottom knives bolts | 6 |

| Bottom knives center | 2 |

| Bottom knives end | 1 |

Key Specs

| Bale | 80x90 cm 3x3 ft |

|---|---|

| Width | 80 cm 32 in. |

| Height | 90 cm 35 |

| Length | 60 up to 300 cm 24 up to 118 in. |

| Number of knotters | Four |

| Knives | 11, 7, or 6 |

| Machine - Width | 2.76 m 9.1 ft |

| Machine - Height | 2.7 m 8.9 ft |

| Machine - Weight | 7,700 kg 16,975 lb |

| Minimum tractor requirement | 86 kW 115 PTO hp - no Pre-Cutter 97 kW 130 PTO hp - with Pre-Cutter |

Bale dimensions

| Bale | 90x90 cm 3x3 ft |

|---|---|

| Width | 80 cm 32 in. |

| Height | 90 cm 35 in. |

| Length | 60 up to 300 cm 24 up to 118 in. |

Pickup

| Intake width | 220 cm 86 in. |

|---|---|

| Pickup diameter | 25.6 cm 10 in. |

| Number of tine bars 4-5 | Four |

| Tine spacing | 6.6 cm 2.6 in. |

| Pre-compression roller baffle | |

| Pickup fixed gauge wheels | |

| Pickup caster gauge wheels - pivoting | |

| Pickup floating | |

| Pickup protection |

Bale chamber

| Number of plunger strokes | 45 spm |

|---|---|

| Plunger stroke | 69.5 cm 27 in. |

| Plunger roller size | |

| Density control | Three hydraulic cylinders |

| Number of hydraulic cylinders | |

| Bale chamber length | 305 cm 120 in. |

| Control | ISOBUS - GreenStar™ 2 1800 or GreenStar 3 2630 |

Knotting system

| Number of knotters | Four |

|---|---|

| Cleaning system | |

| Knotter tracking system | |

| Twine capacity (rolls) | 30 |

Intake system

| High-capacity rotor | Yes |

|---|---|

| Knives | 11, 7, or 6 |

| Cutting length | 44 mm 1.7 in. or 88 mm 3.5 in. |

| Knife protection | Individual spring |

| Knife cleaning system | |

| Slide out floor | Yes |

| Driven crop roll (opt) |

Wheels and axles

| Single axle | 600/50/22.5 or 710/40R/22.5 |

|---|---|

| Tandem axle steered (optional) | 500/55/20 or 550/45/22.5 |

| Brakes system | Optional hydraulic |

Machine dimensions

| Length | 7.8 m 25.6 ft |

|---|---|

| Width | 2.76 m 9.1 ft |

| Height | 2.7 m 8.9 ft |

| Weight | 7,700 kg 16,975 lb |

| Minimum tractor requirement | 86 kW 115 PTO hp - no Pre-Cutter 97 kW 130 PTO hp - with Pre-Cutter |

Additional information

| Weighing device (opt) | |

|---|---|

| Greasing system | |

| Large square baler connection | |

| Large square baler control | |

| Storage box | |

| Humidity sensor (opt) | |

| Date collected |

Would you like more information?

Free Parts Delivery to

Drop Boxes!

OUR DEPARTMENTS

DEALER TRANSFER

OUR INVENTORY

OUR PRODUCTS

© Copyright 2017 - 2025 Ballweg Implement All Rights Reserved. Site by EquipmentLocator.com