On-screen monitoring, logging, and performance mapping

Exclusive John Deere technology

Exclusive John Deere technology

Data-driven decisions

Data-driven decisions

Harvest Monitor is an industry-exclusive technology from John Deere. Harvest Monitor gathers and analyzes valuable harvest information, enabling sugarcane producers to make smarter decisions that drive down harvesting costs and improve overall farming practices.

From the cab, the operator can monitor total tons harvested, harvester productivity, trash percentage, and fuel consumption. The operator can then use this information to make on-the-fly adjustments to optimize performance.

SmartClean system is the latest enhancement of Harvest Monitor that allows automatic control of primary extractor fan speed based on the operator’s preferences in order to obtain the most profitable balance between cane cleanliness and reduced loss.

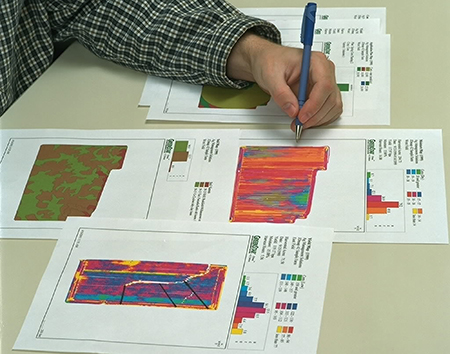

Through the John Deere Operations Center, the data can be processed to generate yield and other valuable maps and reports that will guide producers into making the right decisions on soil and water management, chemical application, crop renewal, field layout, equipment logistics, and much more.

Harvest Monitor features

Harvest Monitor installed on a CH960

Harvest Monitor installed on a CH960

Harvest Monitor is much more than just a yield monitor. It includes:

- Optical yield monitor

- Elevator optical extraneous matter (trash) monitor

- Primary extractor cane loss monitor

- Primary extractor residue (trash) discharge monitor

- Fuel per ton monitor

- Pour-rate monitor

- Elevation monitor

- Transport load counter

Harvest Monitor was designed to operate efficiently in all weather conditions. It is a low maintenance system with no additional wear items thanks to its optical technology that does not require direct contact with the cane.

Optical yield and trash monitor technology

Harvest Monitor

Harvest Monitor

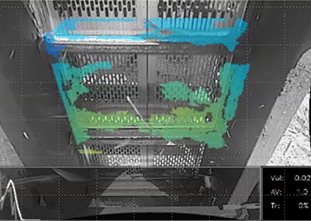

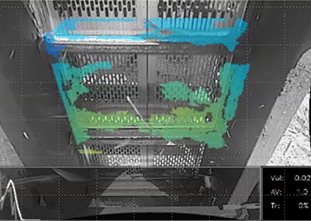

High-resolution, stereoscopic optical sensors and pattern recognition technology are used to scan the flow of cane as it passes through the elevator, identifying cane volume and differentiating it from trash. Four light-emitting diode (LED) lights illuminate the sampling area to ensure uninterrupted visual clarity.

Flow of cane being scanned

Flow of cane being scanned

Image recognition

Image recognition

The system converts the volumes to mass in order to obtain tons of cane and extraneous matter level.

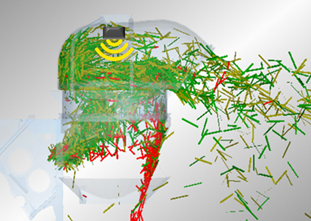

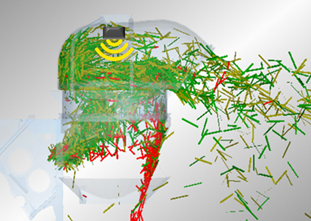

SmartClean system, an intelligent way of cleaning cane

SmartClean illustration

SmartClean illustration

With the use of sensors, the SmartClean system detects cane being lost through the primary extractor and displays it on the CommandCenter screen as an index. The level of residue or cane leaves being removed is also detected and displayed as an index.

Aiming at the best economic outcome for the operation, the operator selects the target level of the following parameters and lets the system continuously and automatically find the appropriate primary extractor fan speed:

- Elevator extraneous matter (trash)

- Primary extractor cane loss

- Primary extractor residue discharge

SmartClean system setting page

SmartClean system setting page

SmartClean enables operational consistency throughout the day regardless of weather conditions and individual operator practices. Understanding the residue level is important for biomass power generation projects to determine residue collection logistics and viability.

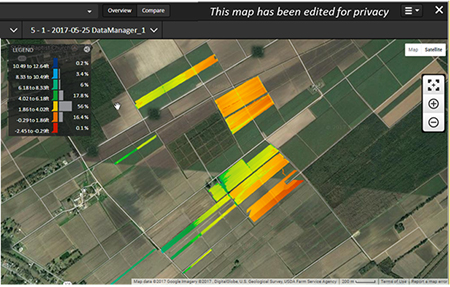

Georeferenced data

StarFire™ Receiver

StarFire™ Receiver

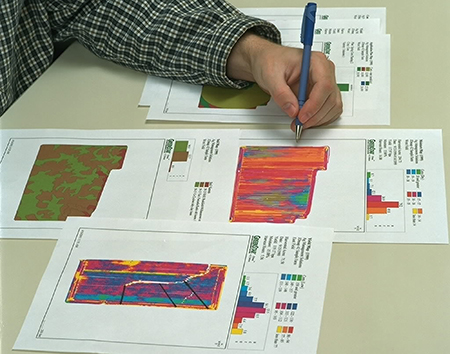

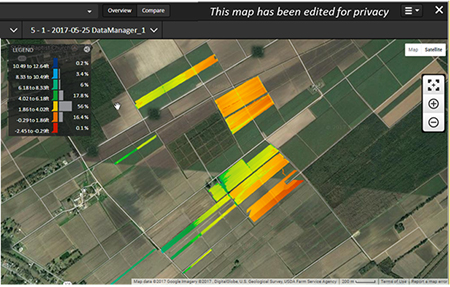

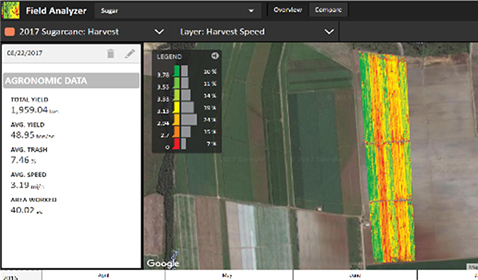

Sugar cane field yield map

Sugar cane field yield map

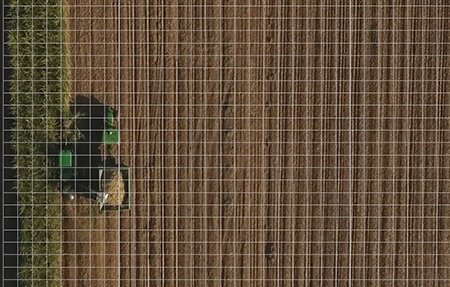

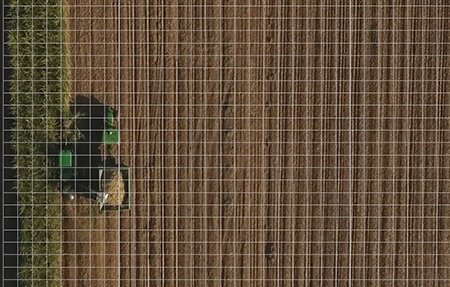

Data points are georeferenced to precise field locations using global positioning system (GPS) technology. With appropriate software, a variety of informative maps can be generated. The system operation requires a GPS receiver.

Data-driven smart decisions on the go

CH960 operating in the field

CH960 operating in the field

With SmartClean activated and based on live information, the operator can make other quick adjustments to the harvester, like ground speed and FieldCruise™ settings, to maintain the most profitable harvesting rate while delivering the preferred level of cane quality and reduced loss.

On-screen monitoring

Home page showing Harvest Monitor information (LH) and video (RH)

Home page showing Harvest Monitor information (LH) and video (RH)

While harvesting, the display will show:

- Harvester pour rate (ton/h)

- Extraneous matter (trash percentage)

- Primary extractor cane loss (index)

- Primary extractor residue discharge (index)

- Fuel consumption (L/ton or gal./ton)

- Yield (ton/ha or ton/acre)

- Transport load count

- Live elevator cane flow video

The CommandCenter display layout is configurable so the operator can have Harvest Monitor and SmartClean system displayed together on the same screen. Average, best, and current values of extraneous matter, fuel consumption, and pour rate are displayed instantaneously or as historical figures. Also available on the display is a summary report of all data.

A yield map can also be seen on the display, as well as live video of cane as it flows through the elevator.

Transport load counter

To keep records of the number of wagons completed, the operator will click the “Save Load” soft key every time a unit is loaded. The screen will show the total loads from a field, shift, whole season, or another preselected period of time. The sugar mill destination can also be recorded for each load.

Primary extractor fan blades

Primary extractor fan blades

Chopper blades

Chopper blades

The information may also help to determine if the chopper and extractor fan blades need to be replaced, or if other related service is required in order to maintain optimum operating performance.

In-field equipment transloading into highway trucks

In-field equipment transloading into highway trucks

Multiple harvesters

Multiple harvesters

The live yield data simplifies daily logistics decisions, including the number of transport units required and the correct timing to efficiently complete the assigned cane quota. In addition, field harvesting progress and remaining unharvested area can be seen on the screen for a great visual of the operation that can facilitate the transition to the next field.

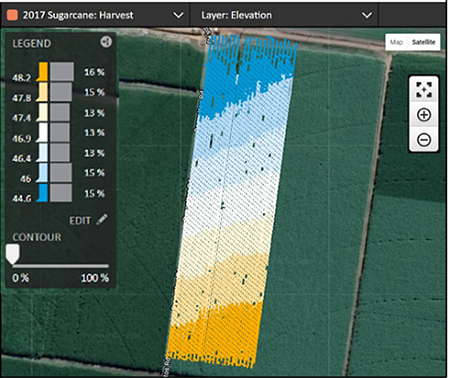

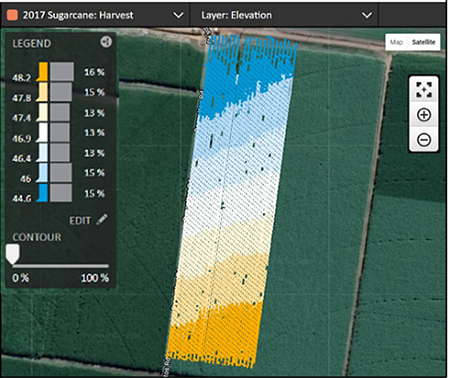

Elevation monitor

Surveying the field while harvesting

Surveying the field while harvesting

Field elevation map

Field elevation map

Georeferenced samples that include elevation readings are taken every second. As the harvester travels down each row, numerous elevation readings representing the topography of the area harvested are recorded.

Example of a typical field:

- Row spacing: 1.5 m (4.9 ft)

- Operating speed: 5.4 km/h (3.4 mph)

- Readings per hectare: 4,444

- Represented area: 1.5 m by 1.5 m (4.9 ft by 4.9 ft)

Field elevation map

Field elevation map

The maps and reports will help to determine the best solutions for:

- Chemical application

- Water management

- Cultivating practices

- Gap planting

- Crop renewal

- Variety selection and performance

- Seed rate

- Land leveling

- Field layout

- Equipment operation management

- Logistics

Information can also be used to evaluate results of previously implemented solutions to make adjustments if needed.

*Google Earth is a trademark of Google LLC.

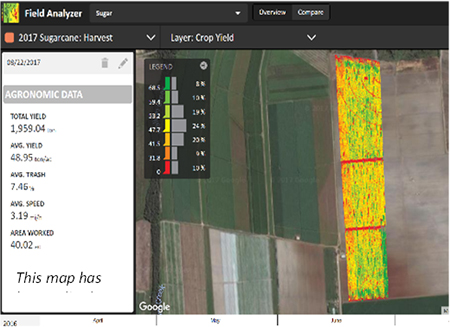

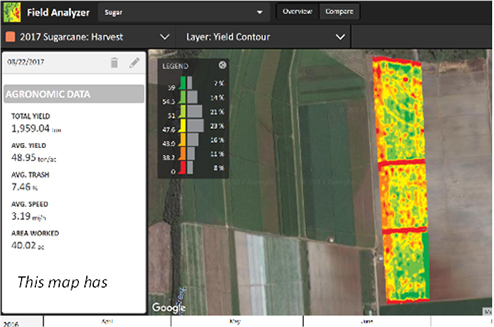

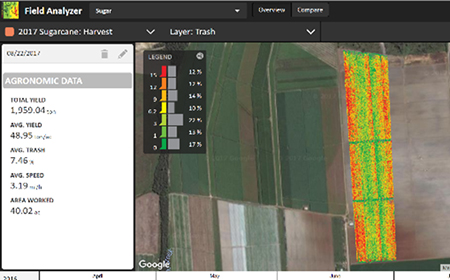

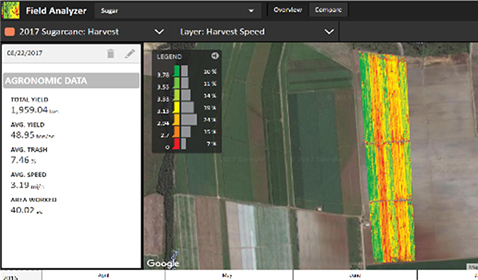

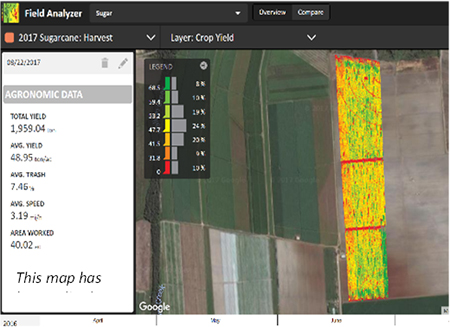

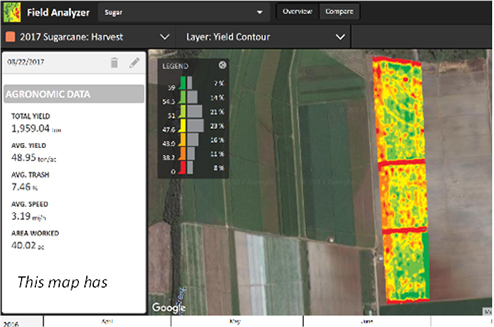

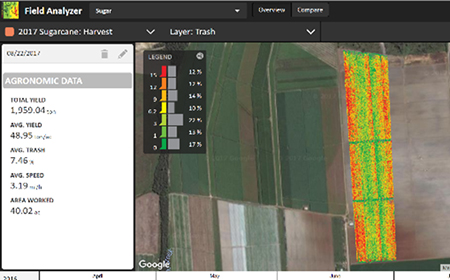

Mapping and data management

Decisions on agronomical practices and logistics

Decisions on agronomical practices and logistics

The Harvest Monitor data can be processed through John Deere’s Operations Center to generate maps and reports that will help optimize operations.

Different types of maps can be created for a clear visualization of current farm conditions:

- Yield variability

- Harvester productivity

- Fuel consumption

- Extraneous matter

- Field elevation

Examples of generated maps

Crop yield map

Crop yield map

Yield contour map

Yield contour map

Extraneous matter (trash) map

Extraneous matter (trash) map

Harvester speed map

Harvester speed map

Calibration

CH570 working with weigh wagon

CH570 working with weigh wagon

During harvesting, Harvest Monitor can be calibrated manually by entering weight information for the load supplied by the mill or from a weight wagon on operations that use it.

The maps can also be calibrated using field report data supplied from the sugar mill.

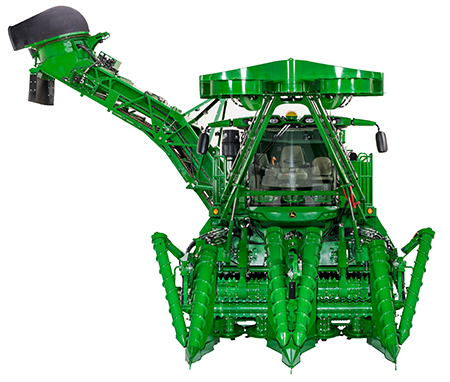

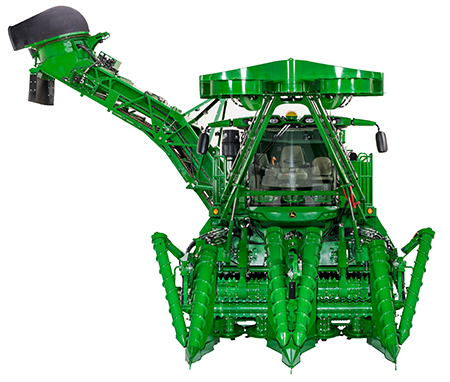

CH9 Series Two-Row Harvester

CH9 Series Two-Row Harvester

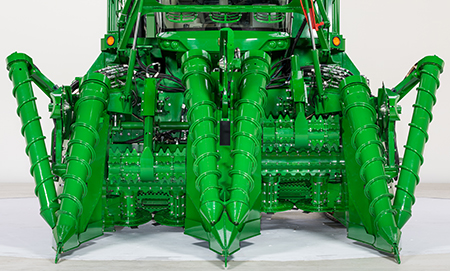

The John Deere CH9 Series Two-Row Harvester provides double the productivity of a single row-unit in most conditions by harvesting two rows of cane simultaneously at the same speed.

Feature benefits:

- Loads wagon in half the time

- Reduces infield transport requirement by 28 percent

- Reduces fuel consumption by 30 percent

- 36 percent fewer operators are needed

Functionality:

Since the CH9 Series models harvest at the same speed as the single-row units in most conditions, the wagons are loaded in half the time, reducing total infield transport equipment cycle time considerably. In a typical operation, this translates into 50 percent fewer harvesters, 28 percent fewer tractors and wagons, and 36 percent fewer operators required per front while saving 30 percent in fuel. In multi-front operations, this additional harvesting capacity can also be used to decrease the number of fronts by increasing their quotas. Regardless of the solution adopted, the total number of operators, tractors, wagons, and harvesters is reduced significantly.

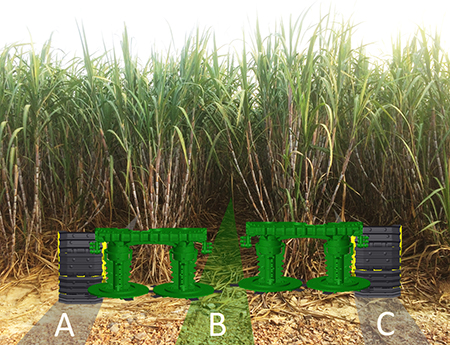

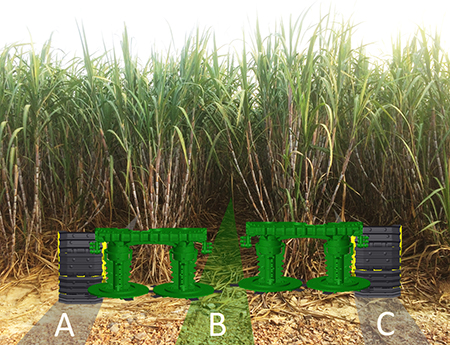

Controlled traffic with CH9 Series (A - hardpan interrow, B - undisturbed interrow, and C - hardpan interrow

Controlled traffic with CH9 Series (A - hardpan interrow, B - undisturbed interrow, and C - hardpan interrow

The CH9 Series tread matches the row spacing so the tracks travel centered on the interrow away from the stubble. By straddling two rows, the center interrow remains untouched, leaving 50 percent of the rows are undisturbed. In addition, the compacted area is reduced by 60 percent, fostering better growing conditions for improved yield and ratoon life.

Feature benefits:

- Matching tread to row spacing

- 60 percent less compacted area

- Untouched center interrow for 50 percent of rows undisturbed

- Improves yield and ratoon life

- 30 to 50 percent cane loss reduction

Root system development with and without compaction

Root system development with and without compaction

Functionality:

By straddling two rows, the center interrow remains untouched so 50 percent of the rows are undisturbed. In addition, the compacted area is reduced by 60 percent. Thanks to better cane growing conditions fostered by the John Deere two-row harvester system, improved yield and ratoon life are expected.

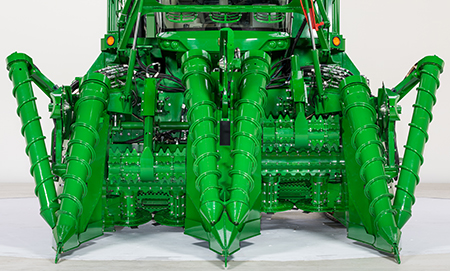

CH9 Series cleaning system in action

CH9 Series cleaning system in action

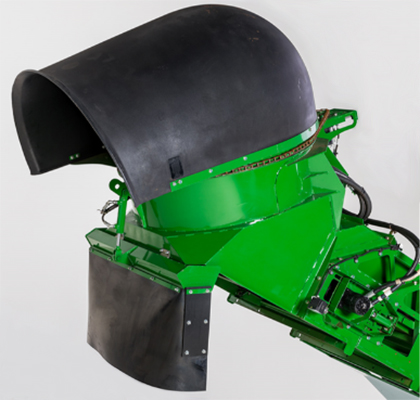

Wider entry to the primary extractor, less billet contact with the fan, and a 78 percent larger secondary extractor reduce cane loss while maintaining low extraneous matter levels. In addition, only 50 percent of the uncut rows are exposed to contact with the harvester for further loss reduction.

Feature benefits:

- Low extraneous matter levels

- 30 to 50 percent cane loss reduction

- Operate at low fan rpm to save fuel

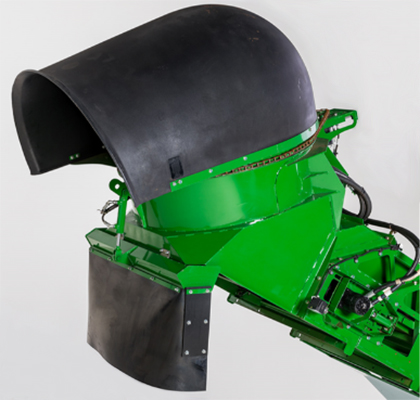

Primary extractor with wide cane entry

Primary extractor with wide cane entry

122-cm (48-in.) secondary extractor

122-cm (48-in.) secondary extractor

Functionality:

Twice the pour rate of a single-row unit required reengineering of the cleaning system to deliver high-quality cane. The CH9 Series Sugar Cane Harvester optimizes the use of the primary extractor cleaning area with wider entry offered by the longer chopper drums. It is in this first section where most of the trash removal takes place. Relocating the fan further back and tapering the cane inlet greatly contributes to cleaning efficiency and reduced loss.

Lower loss is also possible thanks to the higher cane flow that minimizes the risk of billets being pulled away by the fan.

A redesigned, higher-capacity secondary extractor with tapered inlet and 78 percent larger area provides even more cleaning before the cane is loaded into the wagon.

CH9 Series Two-Row Harvester

CH9 Series Two-Row Harvester

The John Deere CH9 Series Two-Row Harvester was designed with both durability and value in mind. CH9 Series components can handle the most unforgiving conditions while providing dependable performance throughout the harvest. Longer life and ease of service dramatically reduce downtime and boost productivity, putting more money in your pocket where it belongs.

Feature benefits:

- Heavy-duty tracks double the life before a major overhaul is needed

- 50 percent larger displacement engine

- High-wear resistant elevator doubles the hours before major repair is needed

- Robust final drives with 60 percent longer life

Rugged CH9 Series Sugar Cane Harvester

Rugged CH9 Series Sugar Cane Harvester

Functionality:

The CH9 Series components have been overdesigned to ensure long-term durability. The John Deere 13.6L (830-cu in.) engine is 50 percent larger than the CH570 9.0L (549-cu in.) engine, and the Tier 3 option uses no more than 70 percent of the maximum power capacity available for other applications. The harvester uses John Deere 850 Crawler Dozer tracks that are two levels above the single-row tracks and won’t need to be refurbished during the season. The elevator is 30 percent larger, and it uses harden steel floors, strips, and sprockets plus heavy-duty slats and bearings. Higher torque capacity gears and bearings are used on the final drive, which provide 60 percent longer life.

CH9 Series equipped with RowAdapt in base

CH9 Series equipped with RowAdapt in base

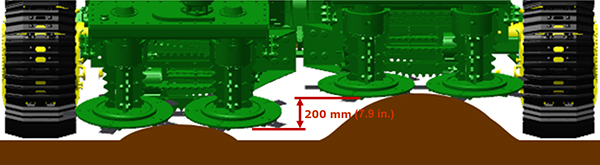

With the John Deere exclusive RowAdapt system, the CH9 Series Sugar Cane Harvester adjusts automatically to different row profiles, row cultures, and changing terrain.

Feature benefits:

- Independent basecutter control system adjusts the cutting height for each row individually to compensate for terrain variations.

- Contour basecutter height control system ensures the cane is cut at the desired height, resulting in higher sugar yield, cleaner cane, and healthier stubble for improved future crops.

- Floating crop divider technology allows the crop dividers to follow the ground profile independently without plowing to reduce soil content, cane losses, and soil disturbance while efficiently lifting downed cane.

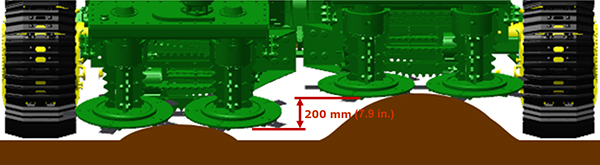

Basecutters adapt to row height variations

Basecutters adapt to row height variations

Functionality:

Once the contour basecutter height control and floating crop divider have been enabled, the RowAdapt system is ready to go to work.

The basecutters are independent and will accommodate height differences of up to 200 mm (7.9 in.) between the two rows being cut on uneven terrain.

The crop divider floating control system is calibrated so that the appropriate pressure is exerted on the interrow to allow the base of the crop dividers to barely contact the ground. At the same time, it keeps the toe under lodged crop so that the scrolls lift up and feed the cane effectively into the harvester throat.

The contour basecutter height control system uses the crop dividers’ position and disk cutting pressure inputs to operate. The system automatically adjusts to the target cutting height selected by the operator.