John Deere 60-inch Heavy-Duty Rotary Broom for X700 Lawn Tractors, select Compact Tractors

60-inch Heavy-Duty Rotary Broom

for X700 Lawn Tractors, select Compact Tractors

- Clean everything from dirt and leaves or even 2-inches of snow with this versatile broom

- Angle broom from 0-27 degrees, right or left

- Choose from 9-different sweeping height positions, in increments of 5 inches

- Attach broom in minutes, no tools needed, with the optional front Quick Hitch system

- Angle from seat with optional hydraulic angling

Features

60-in. (152-cm) Heavy-Duty Rotary Broom

60-in. (152-cm) Heavy-Duty Rotary Broom

60-in. (152-cm) Heavy-Duty Rotary Broom

NOTE: X729 Tractor shown with optional BM20753 front-light kit.

The 52-in. (132-cm) Rotary Broom increases tractor versatility by allowing it to be used for a variety of sweeping jobs. The broom effectively meets the needs of commercial, farm, home, and estate operators with four-season versatility:

Spring

The broom can be used to dethatch lawns, and it cleans off tennis courts quickly and effectively.

Summer

The broom effectively performs a wide variety of sweeping jobs, including cleaning sidewalks, parking lots, driveways, construction job sites, and barns. It can also be used for backfilling trenches.

Fall

The broom can be used to sweep leaves and windrow pine needles. It sweeps artificial turf and cleans up spectator areas after sporting events.

Winter

It effectively moves up to 2 in. (5 cm) of snow, which may eliminate the need for a snow thrower, depending on the operator's geographic area.

The 52-in. (132-cm ) Rotary Broom is compatible with X700 Series and 1023E, 1025R, 1026R, model year 2016 and older 2025R and 2032R, 2305-2720, 2210, 4010, 4110, 4115, and 4100 Tractors.

NOTE: If a compact utility tractor is set up for an AutoConnect™ mid-mount mower, the quick-connect drive shaft and rear lift link must be removed from the tractor before installing the rotary broom.

Polypropylene and steel wafers

Polypropylene and steel wafers

Polypropylene and steel wafers

The broom section is assembled with 32 polypropylene wafers.

NOTE: In certain applications, it may be desirable to equip broom with all or some steel wafers.

Optional steel wafers are available:

- Steel wafers do a good job of breaking material loose.

- The steel wafer is for aggressive action.

- Polypropylene wafer is good for cleaning any surface.

- Assemble with alternating polypropylene and steel wafers for good breaking loose and cleaning of material.

- Assemble steel wafers on ends for extra curb cleaning.

Replacement wafers, packaged 16 to a box, can be ordered from Parts.

It is recommended that all 32 wafers be replaced at the same time for even wear.

Wafer bristles have a convoluted design for a good flicking action.

Broom-head float

Casters provide a quick response, allowing the head to float and follow the terrain. The broom head also articulates for undulating terrain.

An adjustable, threaded rod allows the broom to float and follow the terrain.

Brush wear and pattern adjustment

Acme screw and knob for infinite pattern control

Acme screw and knob for infinite pattern control

An Acme screw and knob is used for infinite control of pattern. It also allows control of the depth of the bristles beyond raising the hitch as bristles wear down or more ground contact is needed.

Shields

Shields

Shields

The front drive shield provides additional protection against material becoming jammed in the sprocket and chain. The gearbox hood shield hinge and spring provide protection, yet allow convenient access to power take-off (PTO) shafts.

A hood debris deflector is available as an attachment:

-

Helps direct debris and dust ahead of broom

-

Can be adjusted up or down to help control material being swept

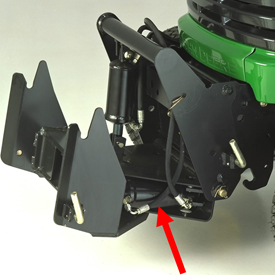

Parking stand

Parking stands

Parking stands

Parking stand is standard equipment:

- Helps keep broom level when hooking it up

- Takes broom weight off of the bristles during storage

Front quick-hitch mounting system - X700

Front quick-hitch mounting system

Front quick-hitch mounting system

The broom slips over and locks into the front quick-hitch with attached snap pins:

- Fast and easy installation with no tools or loose parts

-

Same hitch is used for blade, broom, snow blower, and snow thrower

NOTE: The 60 Rotary Broom requires use of the newer BM19782 front quick-hitch for installation on X Series Tractors. Interference will occur if installed using a BM17347 quick-hitch.

Lever-lock pins and stands help keep broom level when hooking up. They are also used to keep broom weight off of bristles when storing the unit.

Front hitch hookup – Compact utility tractors

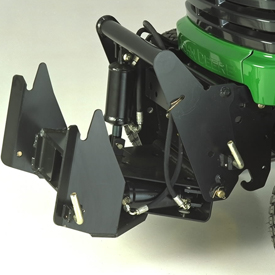

Model year 2017 and newer 2032R, 2038R, 3120-3720, and 3033R-3046R Tractors - front 3-point hitch with A-frame adapter

Front 3-point hitch with A-frame adapter

Front 3-point hitch with A-frame adapter

Works with a variety of implements

Works with a variety of implements

The front 3-point hitch is designed to be a more robust solution for operators who would like to use front implements. This design is the standard in Europe, where the majority of tractors are sold with front hitches. Advantages of a front 3-point hitch over a Quik-Tatch™ style hitch include the following:

- 90 percent of the front hitch can be left on the tractor when a loader is installed. (Only the lower draft arms, top link, and A-frame need to be removed. This is accomplished with quick-release pins.)

- 100 percent of the hitch can be left on when a mid-mount mower deck is installed (cannot raise and lower the hitch, so it is not recommended an implement be left on the hitch, but it can be installed).

- The A-frame adapter is an industry standard (like iMatch™ system) with which other implement manufacturers design interfaces. There are other products on the market, like front mowers, that can be used with this front hitch.

- The A-frame adapter allows for tool-free, quick change between implements.

- The same front hitch can be used with the 366 Front Blade, 59 Snow Blower, and 60 HD Broom.

Click here for the front 3-point hitch bundle breakdown.

NOTE: The front 3-point hitch only works on model year 2017 and newer 2032R, 2038R, 3033R-3046R and 3120-3720 Tractors.

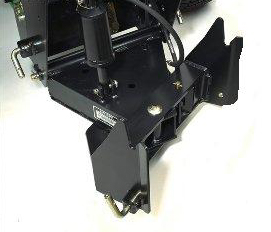

Small-chassis tractors - Quik-Tatch front hitch

Quik-Tatch front hitch shown with 52 Broom

Quik-Tatch front hitch shown with 52 Broom

Hitch slips over and locks onto frame with attached snap-pins:

- No tools required (after initial installation)

- No loose parts to find

- Same hitch works with all front-end attachments: blade, broom, snow blower, and snow thrower

NOTE:

1) 2305, 2025R 2320, 2520, model year 2016 and older 2032R, 2720, 2210, 4010, 4110, 4115, and 4100 Tractors must be equipped with front-attaching support kit for use with the Quik-Tatch front hitch.

2) If the operator plans to use a Quik-Tatch front hitch with an OnRamp™ Mower (2025R, 2320, 2520, 2032R, 2720, and 4115 only), a front hitch/mid-mower combo bracket will be needed to retain a tool-free change between the front hitch and the mid-mower deck.

Lever lock pins and stands help keep broom level when hooking up. Also used to keep broom weight off of bristles when storing unit.

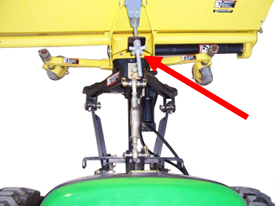

Hydraulic angling - X700

Hydraulic-angling cylinder

Hydraulic-angling cylinder

Standard hydraulic angling allows positioning the implement straight ahead or at an angle:

- Straight ahead and infinite positions left or right

- The operator can change the angle from the tractor seat for increased productivity.

- Allows moving material off to the side and out of the way

- Allows working in a back-and-forth operation (no need to deadhead back to the origin)

- Minimizes driveline vibration in rotary broom applications, when the broom is angled

- Power take-off (PTO) shaft U-joints operate smoothly, even when the implement is angled.

Hydraulic angling – Compact utility tractors

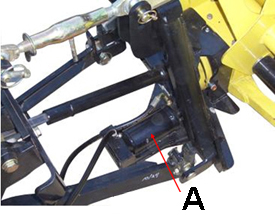

Hydraulic angling cylinder - 3120-3720 CUTs (A)

Hydraulic angling cylinder - 3120-3720 CUTs (A)

Hydraulic angling for small-chassis tractors

Hydraulic angling for small-chassis tractors

Standard hydraulic angling allows positioning the broom head straight ahead or angled up to 30 degrees (left or right):

-

Allows moving material off to right or left side and out of the way

- Allows sweeping in a back-and-forth operation (no need to deadhead back to origin)

To enable hydraulic angling (shown above), direct mounting frame with pivot cylinder is required:

- Allows positioning broom at any angle up to 30 degrees (left or right)

-

Operator can change angle from tractor seat with the dual selective control valve (SCV) joystick for increased convenience and productivity

The power take-off (PTO) shaft has constant velocity U-joints to help minimize driveline vibration when broom is angled.

Broom head can be shifted to the side approximately 2 in. (5 cm) to cover tire tracks when unit is angled 15 degrees.

NOTE:

-

When unit is side-shifted and angled up to the maximum 30-degree position, the entire tire track may not be covered.

-

Each platform has a different angling setup due to the different style of hitches, but they all angle 30 degrees to the left or the right (i.e., the hydraulic angling for the small-chassis cuts is different than for the mid-chassis Ten Series, which is different than the mid-chassis Twenty Series).

Front power take-off (PTO)

Front PTO (appearance varies by tractor model)

Front PTO (appearance varies by tractor model)

The front implement is powered by the tractor's 2000-rpm front PTO:

- Engaged by the tractor's PTO clutch for smooth startups and a long life

- Easily installed and removed from tractor

- Can remain on tractor for front blade, rotary broom, and snow blower applications

Key specs

| Clearing width | Sweeping path Front quick-hitch: at 27 degrees: 53.5 in. 136 cm Front 3-point hitch: at 30 degress: 50 in. 127 cm |

|---|---|

| Brush | Diameter 26 in. 66 cm Number of wafers 32 Width: 60 in. 152 cm |

Clearing width

| Broom straight | |

|---|---|

| Broom angled | |

| Sweeping path | Front quick-hitch: at 27 degress: 53.5 in. 136 cm Front 3-point hitch: at 30 degrees: 50 in. 127 cm |

Brush

| Diameter | 26 in. 66 cm Width: 60 in. 152 cm |

|---|---|

| Material | |

| Number of wafers | 32 |

| Drive | Front power take-off (PTO) |

| Sweeping height | |

| Speed | |

| Top speed |

Angling method

| On X700 | Hydraulic |

|---|---|

| On compact utility tractors | Hydraulic (dual selective control valve [SCV] joystick controls angling) |

Hydraulic angling positions

| Right and left | Front quick-hitch: Any position up to 27 degrees left or right Front 3-point htich: Any position up to 27 degrees left or right |

|---|

Hood

| Type | Steel three-piece bolt-together |

|---|

Unitized structure material

| Housing | |

|---|---|

| Frame | |

| Lateral float |

Drive system

| Input | |

|---|---|

| Center drive | |

| Brush drive | Front power take-off (PTO) |

| Brush shaft | |

| Broom gearbox reduction | Three-to-one, spiral bevel gear, synthetic extreme-pressure lubricant, shear pin protected, central location |

| Final drive | Three-to-one, spiral bevel gear, synthetic extreme-pressure lubricant, shear pin protected, central location |

Caster wheels

| Size | |

|---|---|

| Adjustment |

Storage stands

| Storage stands |

|---|

Broom head protection

| Type | Shear bolts (broom comes with four extra bolts) |

|---|

Weight

| Weight (broom only) | |

|---|---|

| Shipping weight |

Additional information

| Date collected |

|---|

Would you like more information?

Free Parts Delivery to

Drop Boxes!

OUR DEPARTMENTS

DEALER TRANSFER

OUR INVENTORY

OUR PRODUCTS

© Copyright 2017 - 2025 Ballweg Implement All Rights Reserved. Site by EquipmentLocator.com